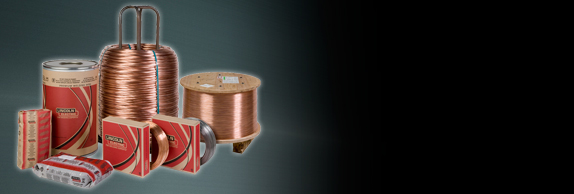

Submerged Arc Wire

A variety of welding flux and wire designed to be paired together to meet any industry specific welding requirement. Over 150 combinations are available for single and multiple pass welding in both automatic and semi-automatic applications.

Lincolnweld L-60

Premierweld IN61

Top Features

- A low carbon, medium manganese, low silicon general purpose submerged arc electrode.

- A good choice for various applications with single or multiple pass submerged arc welding.

- Capable of producing weld deposits with impact values exceeding 27 J at -40C when used with Premierweld BF-1 Flux

Lincolnweld L-61

Lincolnweld LA-100

LNS 164

LNS 304L

LNS 309L

LNS 316L